Marvin DeWitt was the Henry Ford of the turkey industry. Like Ford, he built a vertically integrated business. But he had a slow start.

In 1933, during the Great Depression, his family returned from Rudyard, Michigan, to Borculo. There, Marvin attended his last year of school (the eighth grade) and worked on both his family’s farm and his neighbors’ farms. L

Eventually, he got a job at Speet Dairy in Holland, then Heinz. To get to work, he commuted the nine miles on foot until he’d saved enough money to buy a very used 1924 Chevrolet.

At the urging of his friends, Marvin left his family’s church, Borculo Christian Reformed, and joined Ottawa Reformed Church. While attending Ottawa Reformed, he met Jerene Bekius.

More: Steve VanderVeen: Marvin DeWitt and life on the farm

In 1935, Marvin’s brother, Bill, snagged a full-time job at Grand Haven Brass. In 1937, through Bill, Marvin landed a part-time job. To make extra money, in 1938, Bill and Marvin bought 14 hens and three tom turkeys.

While Bill, then 24, had enough money to pay for his half, Marvin, then 17, had to borrow money from his sister Sena.

As their turkey flock began producing eggs, the brothers discovered their operation was too small to interest a hatchery. Finally, with much persuasion from Marvin, Dick, Jack, and Ben DeWitt (not related) of Zeeland Hatchery took the eggs.

Bill and Marvin bought 60 breeder hens and a few more toms. By 1939, the year Marvin and Jerene were married, the operation was producing 200 turkeys for Christmas meals.

Bill and Marvin continued to work at Grand Haven Brass. But in 1941, Marvin, upset over his wages, quit. Two months later, he was working full-time at Hart and Cooley in Holland.

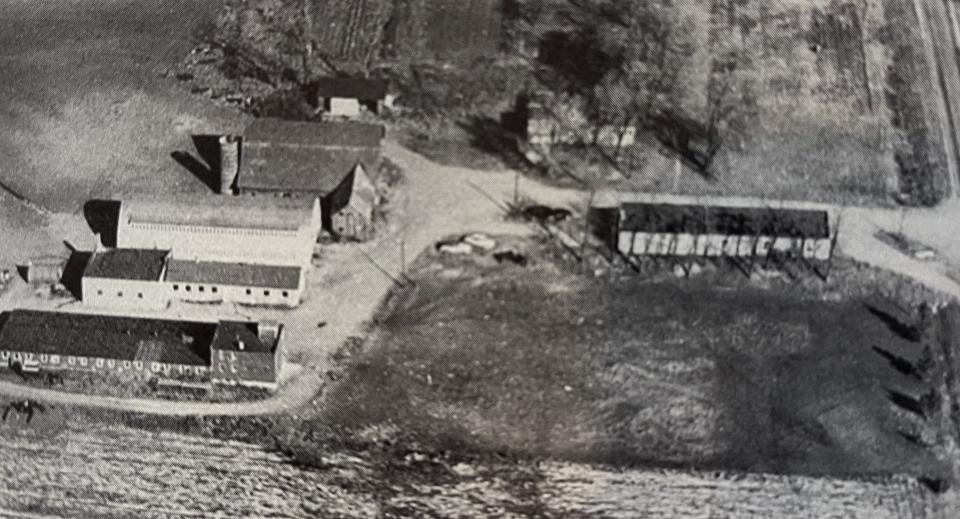

But when his father Gerrit died of cancer in 1941, Marvin quit Hart and Cooley to work on the family farm. Deciding to expand the turkey operation, he went to First Michigan Bank to borrow money to build a 47-by-110-foot shed to raise baby turkeys. To get the loan, he had to convince Jerene, Bill, and Martha (his wife) to be co-signers.

Marvin’s timing was good: World War II began and brought with it the rationing of beef and, consequently, a surging demand for turkey meat.

Bill quit his job in 1943 to help Marvin. At the end of WWII, when there was an oversupply of turkeys, the National Turkey Federation helped the brothers by running national advertisements that associated turkeys with Thanksgiving. By 1947, Bil-Mar was growing 15,000 turkeys per year.

Bill and Marvin’s partnership worked. Bill liked the operations side of the business; Marv was the promoter and visionary. Bill was friendly, soft-spoken, and conservative; Marv was extroverted, boisterous, intense and willing to take risks.

Marvin’s vision was to control every part of turkey production. So, in 1950, the brothers added a small feed mill to their operation. In 1954, they not only built the largest barn for turkey breeding and brooding in the Midwest, they also began offering customers oven-ready fresh and frozen turkeys.

In 1955, Bil-Mar added a brine freezer technique that quickened the freezing process and eliminated the meat’s discoloration.

By 1957, Bil-Mar was selling frozen turkeys to grocery chains, hotels, and distributors like Gordon Food Service. In 1958, they built a modern processing plant. In the 1960s, they began hiring seasonal workers.

In 1961, Bil-Mar started making individual turkey products like boneless breasts, hams, hot dogs, luncheon meats, and sausages — only the third turkey farm in the country to do so —and the first to integrate turkey processing with turkey breeding, hatching and growing.

Subscribe: Get unlimited access to our local coverage

In 1966, they incorporated the company as Bil Mar Foods.

In 1971, Bil Mar Foods started offering frozen dinners to food-service wholesalers and corporate customers, such as airlines and hospitals. Those offerings evolved into a prepared entrées division and later a gourmet specialties line.

In 1972, company sales reached $1 million. In 1973, Bil Mar opened an employee-discount store, which later became the Country Store.

In 1977, Bil Mar introduced Mr. Turkey. Sales exploded, reaching $170 million in 1984.

After the Sara Lee Corporation purchased Bil Mar Foods in 1988, Marvin’s son — Jack — along with other investors, purchased the prepared entrées division from Sarah Lee to form Request Foods.

Information for this story comes from Michael Lozon’s “Mr. Turkey.”

— Steve VanderVeen is a resident of Holland. You may reach him at skvveen@gmail.com. His book, “The Holland Area’s First Entrepreneurs,” is available at Reader’s World.

This article originally appeared on The Holland Sentinel: Holland History: How two brothers and a lot of turkeys became Request Foods